This Content is all about for Digital Weighbridge Scale which is manufactured in Bangladesh by a company named as “Shova Advanced Technologies Limited” under the Brand “SUMO Digital Scale” . We produce various Digital Weighbridge ranging from 20 Ton to 100 Metric Ton . Now we are eagerly thinking for Digital Weighbridge where SSWIM and LSWIM Technology can be used . The main objective of this technology is when a vehicle is in motion it can detect the weight .

We have been engaged in the business of digital weighing scales for more than 10 years now and we can say it with utmost sincerity that we are one of the the most experienced and capable digital weighing scale manufacturers in Bangladesh. We do have the capability and expertise to handle big tenders, tenders that requires to buy products from foreign countries. But, with due respect, it’s quite unfortunate that the government fails to realize its own potential. The potential that we, the domestic businesses have. The scale that are requested in the tenders regularly issued by our government and industries aren’t very different from the scales that we already produce.

As for example our weigh bridges, they are the same as low speed weigh in motion (LSWIM) scales , recently of which a tender had been released, with the only difference being that these scales can weigh while the vehicles are in motion. And by making a few definite changes to our existing weigh bridges, we can easily produce LSWIM scales. LSWIM, more commonly known as SSWIM/WIM scales in other countries, or any other big heavy duty scales always require a lot of different components. Thus no single company can produce the whole thing alone because they are not able to produce all the components by themselves. And even the foreign companies from whom we are trying to buy the product from can only produce the main part of the scale for the basic part of the scale alone and the other required components they would have to bring from somewhere else. And like them we can easily produce the scale and only have to import a few components to finish the total Job. Because we’re weighing scale manufacturers, it won’t be possible for us to produce anything other than scale and certain components related to scales. As for example, security cameras are required in the total installation of a LSWIM scale, we can easily produce the scale but we obviously won’t be able to produce the security cameras. Thus we would have to import them. I hope in the future the government will give these opportunities to us rather than foreign countries. I hope in the future the priority changes to “Made in Bangladesh” .

Here is a Details Description of WIM Technology .

What is WIM System and its history?

WIM System stands for Weighing in Motion. The process of measuring the dynamic tire force of a moving road vehicle and estimating the gross-vehicle weight and the portion of that weight supported by each wheel, axle, or axle group of a corresponding static vehicle is referred to as Weighing in Motion.

In the 50s , WIM was invented in the US (Texas) by Pr Clyde Lee. It was mainly utilized to collect large sample of axle and vehicle loads for pavement design purposes and the ASTHOO pavement design code. The first sensors used for weighing were Bending plates . New technologies of WIM sensors were organized in Europe, such as wire, strip and bar sensors, capacitive, piezo-electric (ceramic, then polymer andthen quarz) , and finally fiber optics from the 70s . In the US Bridge WIM was also introduced in the late 70s and then developed in Europe in the 90s.

The accuracy of WIM systems were significantly developed in the early 2000s and they were used more and more for overload screening and preselection (enforcement).

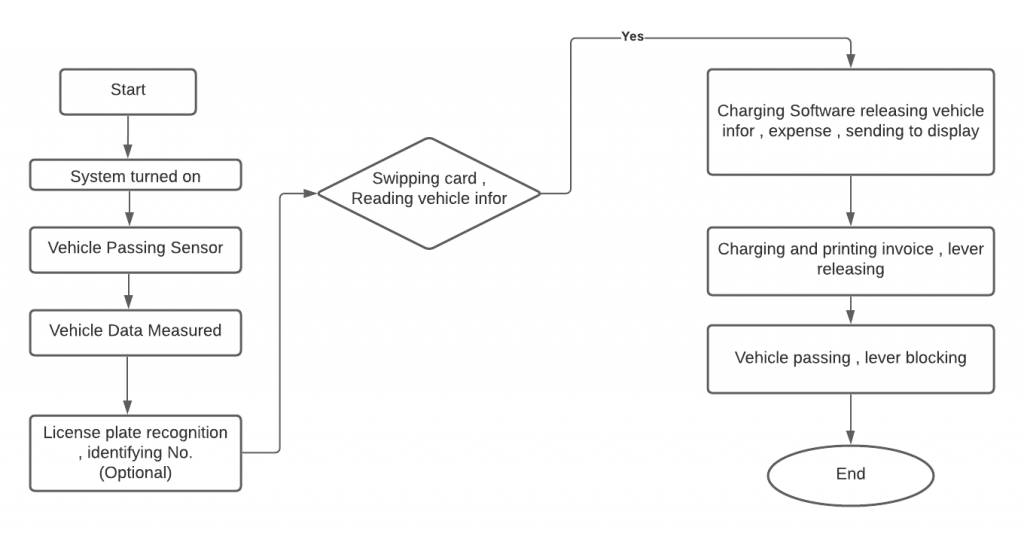

The Flowchart Of WIM Technology

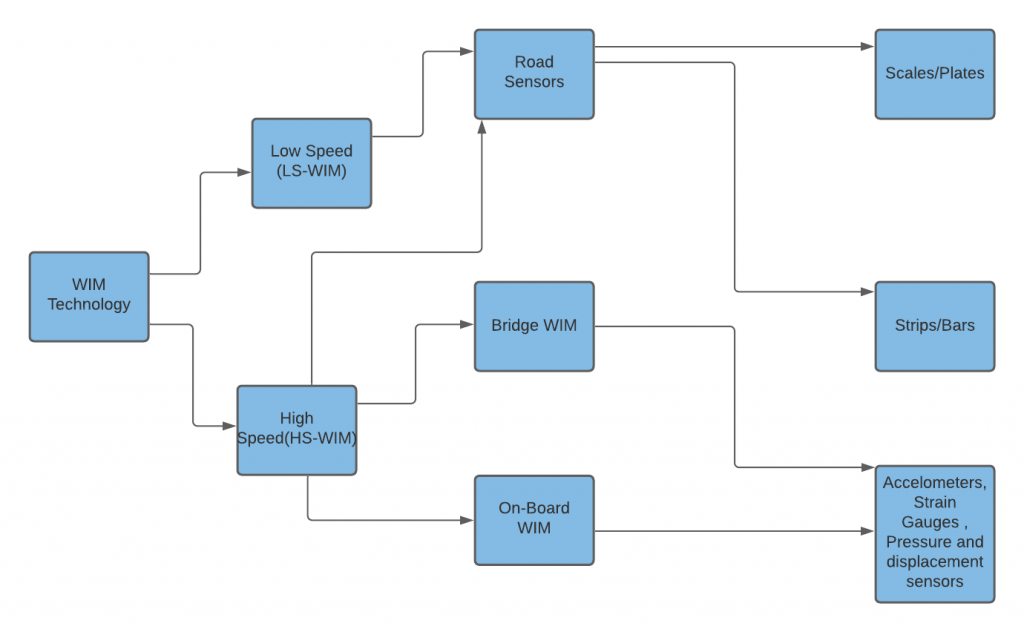

Classification Of WIM Technology

Low and high speed (LS- and HS-)WIM are categorized depending on the WIM location and velocity:

- Slow speed weigh in motion (SSWIM): The weighing process is done on a dedicated area, outside the traffic lane, on a flat and smooth platform which is longer than 30 m, and at a velocity below 5 to 10 km/h, in order to eliminate the dynamic effects of the vehicle and to assume that the tire forces are equal to the wheel static loads. This technology uses mainly load cell scales and is legally approved for direct enforcement or trade.

- High speed weigh in motion (HSWIM ): The weighing process is done in the traffic lane at current speed (i.e. 60 to 90 or 100 km/h), without the need of slowing down or stopping the vehicles. Here in this case sensor is used , amplified by charge amplifier , then a process of A/D converter is happened and then the signal goes to the Embedded Computer.

There are two main technologies of WIM scales:

- Load cell: The plate is rigid for load cell and a series of load cells are mounted between it and the support frame, to measure the vertical forces transferred from the wheel/axle to the plate and then to the frame. In factory , the load cells are calibrated and certified by the legal metrology. This is an accurate process but expensive technology, mainly used for low speed (LS)WIM, but also in some cases for high speed (HS)WIM, mainly for enforcement purposes.

- Bending plates: In this case , the plate is supported by the frame at its edges, and instrumented with stain gauges, which measure the plate bend while a wheel or axle is crossing it. In this case , the bending strains are proportional to the vertical force if applied at the same location. However, this technology is cheaper but less precise than the load cell. It is applicable for HS-WIM.

WIM output

Detailed individual data (per vehicle):

- Unique identification (registration) number

- Date and time stamp (yy-mm-dd + hh:mn:ss:cc)

- Location : road, direction, traffic lane

- Type of vehicle (truck, van, car, 2 power wheel, etc., and class according to a given classification)

- Speed

- Total vehicle length and wheel base

- Number of axles

- Gross vehicle weight and axle loads

- Distances between axles

And in some cases

- Weights per sensor (if more than one sensor per lane)

- Vehicle width or wheel spacing on an axle

- Wheel lateral location

- Calibration coefficient (of the WIM sensors)

- License plate number

- Error code (to validate or eliminate measurements)

Aggregated data (per time period):

These data consist of part or all of the individual measurements summed or averaged over a given period of time (e.g. 6 mn, 1 hr, 1 day, 1 week, 1 month, 1 yr).

Among others:

- Traffic classification (% per types of vehicles over a given time period)

- Classified flow: mean number of vehicles or axles of a given type per time unit

- Histograms of any of the detailed data (type/class of vehicles, speed, vehicle length or axle spacing, GVW or axle load, etc.)

- Means, standard deviations, fractiles of any of the detailed data

Some WIM systems provide only aggregated data, which limits the storage capacity. The aggregated data may be calculated afterwards.

Short time aggregated data (e.g. 6 mn, 1 hr) are used for real time traffic information and management. Long time aggregated data (1 week to 1 yr) are used for statistics, traffic monitoring and road operation or maintenance.

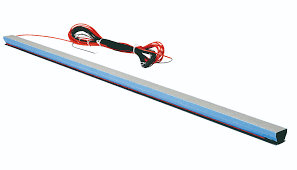

Quartz weighing sensor for HSWIM

This is the main sensor for HSWIM Technology . Actually this sensor detects the motion of vehicle . The velocity range of the vehicle is 0.5 to 105 km/h . The error range of total weight is less than or equal to ± 5% . Axle load error range is ± 10% and speed error is less than or equal to 1 km/h . Working Temperature range is -45 ° C to 80 ° C . Life Cycle is 100 million axle .

Hoping Our Concerning government will look forward to us to bring this new Technologies to our country .

References

- “What is WIM and History” June 22, 2021

http://www.is-wim.org/index.php?nm=2&nsm=1&lg=en

2. “WIM Systems and Output” June 22, 2021